Digital blasting solutions a focus for manufacturer

HENNIE VAN NIEKERK BME offers digital blast planning tools for accurately ensuring that the blasting site is a controlled environment

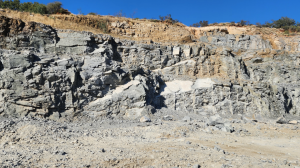

CHALLENGING GEOLOGY BME’s solutions allow quarry operators to seamlessly navigate and enter challenging geological environments

Drone technology, AI and machine learning are setting the development path for blasting in the South African quarrying sector, as they provide futureproof solutions to the traditionally manual methods associated with the quarrying industry, says BME regional technical services manager Hennie van Niekerk.

He believes that these technologies, paired with BME’s blasting solutions, will ensure that the blasting industry in the quarrying sector, as well as the general mining sector, will become more sophisticated, and will ensure enhanced accuracy and optimised safety, effective material fragmentation, operational cost-efficiency and vibration control.

“Our investment in effective blast design software is transforming how quarries app-roach every stage of the blasting process.”

Using advanced software platforms, engineers can simulate complex blast scenarios, taking into account real-world variables such as geology, terrain and environmental constraints, Van Niekerk adds.

Drone technologies, with 3D mapping capabilities, are being incorporated into various departments, including pre-blast planning and analysis, where they are deployed to operate over quarry sites, collect data and provide high-resolution imagery. Such imagery is important for assessing rock formations with the gathering of other real-time data.

When used in conjunction with drones, AI enables access to data that will enable users to account for geographical and environmental constraints, detect hidden weaknesses and identify structural anomalies.

These AI tools will enable engineers to thoroughly analyse the blueprint of AI algorithms for every blast and make informed decisions for future blasting projects.

Van Niekerk adds that AI is addressing factors such as safety, sustainability and cost-efficiency, which, in turn, allow for precision-driven management in the quarrying sector.

Reducing Flyrock

BME follows a holistic approach to reducing, or otherwise controlling, the impact of flyrock by adapting its strategies to a particular site, identifying its geology and anomalies, and using BME digital software and AI to create appropriate blast designs.

“This not only enhances safety by predicting and mitigating risks but also ensures compliance with environmental regulations by minimising dust, noise, air-blast or air- overpressure, and vibrations,” says Van Niekerk.

He notes that the company offers digital blast planning tools for accurately ensuring that the blasting site is a controlled environment. This is achieved using digital planning tools, such as the Blastman, Wallpro and DensDepth, as well as the AXXIS Silver electronic initiation system for accuracy and precision in blast timing.

To ensure controlled capture of charging volumes at the quarry or mining operation, BME deploys its Xplolog system.

The company also provides after-blast and real-time data monitoring solutions for operational protection and improvement, which can be used even after a blasting operation has been completed.

The company aims to further expand on its research and development (R&D) of formulations that reduce environmental impact while maintaining product performance.

One such R&D project, which forms part of BME’s research for “greener explosives”, is the company’s quest to incorporate used oil in its emulsion-based explosives.

Van Niekerk urges mining and quarrying sector players to combine traditional attention to detail with modern innovations to remain relevant in a rapidly changing sector.

“In South Africa and beyond, where quarries are increasingly pressured to balance productivity with safety, community and environmental impact, we are empowering operations to thrive under modern constraints.

“Through our technical expertise, continuous R&D and environmentally-conscious design, BME is not just adapting to the future of quarry blasting – we are actively defining it,” he concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation